Take a trip down memory lane with me for a moment. Think back

to that first major ski equipment purchase you ever made. Perhaps you’re

tired of an endless stream of dull edge skis and ill-fitting rear entry boots

available from your local hill’s rental shop. Or, maybe you’d finally been

cut from the ski equipment hand-me-down welfare trough provided by parents

and relatives. Did you do any research or just dive right into the equipment

acquisition process? After all, ski shops can be a scary place to the uninitiated.

Hopefully you had a wise and experienced 18 year-old salesperson coach you

through the process, asking all the right questions, giving all the right

answers, assuaging all your fears.

n

As much ribbing as traditional alpine ski shops take for high

prices and inefficiencies, they do perform an invaluable consumer education

service to the ski industry as a whole. If this was your experience, good

for you, but have pity on those of us who schlepped to the mega-chain sporting

goods store and bought a whole package for $199 from a clerk who’d skied exactly

two days the season before… and was considered the shop expert.

Whatever your ski equipment purchase history has been, warm

and fuzzy memories or ugly scar on your psyche, you probably sought advice

from friends who skied before you bought. What did they say? Hopefully they

pointed out that cool, air brushed graphics aside, skis were not the most

important part of the package, nor were one-piece day glow Bogner suits.

No, hopefully they told you that the key link between sliding on a slope and

a smile on your face was a proper fitting pair of ski boots. And that goes

for all you one-plankers, too. There’s just no substitute for a pair of boots

that fit well, keep you warm, and translate your body’s inputs directly to

your skis or board. Alternatively, nothing ruins a bluebird powder day faster

and more completely than cold feet, shin bang, and that delightfully painful

rub-rub on your bony ankle protrusions.

My first ski boots were a forty-pound Hanson bear trap model.

They not so much surrounded and protected my 12 year-old feet as clamped and

contorted them. I graduated into a pair of decently fitting rear-entry Salomons

a year or so later, amazingly not abandoning the sport after the excruciating

Hanson experience. The Salomons were okay, and certainly had the requisite

fit adjustment knobs, dials, and gauges that baffled but impressed me. After

several blue square years in the Salomons, I received some front entry Technicas

as a birthday gift. I had my own private moment of enlightenment in those

boots. They fit, my skis carved, and I smiled.

This last summer I had the fortunate experience of receiving

a high-end model of boots as compensation for helping a buddy move from Vermont

to Colorado. (Now why would anyone want to make that move?) My old Technicas

were just on the verge of collapse, so the timing was perfect. I figured

I’d go all the way with this pair, and give my feet a treat. I headed to

a local boot fitter with a great reputation, had custom foot beds made, softened

the forward flex to suit my slender frame and build, and waited for the snow

to fall.

And fall it did in the second week of October, and the new boots

got a brief, pre-season test drive. All I can say is, skip that Starbucks

pit stop in the morning, whatever it takes, but save your money and see a

competent boot fitter if you have any problems at all with your current boots.

Have some custom beds made and any other work needed to your boots to bring

your ski experience to the next level. The level of comfort, control, and

satisfaction you experience from boots that are modified to fit your feet,

and not the average foot of the masses, can make all the difference.

The first step in properly customizing your boots is finding

that friendly, neighborhood boot fitter to whom you’ll entrust your precious

tootsies. But what should the layperson look for? How do you know they’ll

steer you right, do their black art competently, and transform your decent

plastic shells and foam liners into a throne for your feet? After all, a

poor custom foot bed causes more problems than it solves.

Enter MasterFit University.

A traveling road show staffed by some of the ski industry’s most experienced

boot fitters, MasterFit is in the business of training the top boot fitters

of tomorrow. Their one and two day clinics impart boot fitting knowledge

to newbie shop technicians, boot guru pedorthists, and everyone in between.

(A pedorthist is a fancy word for a foot pharmacist. Pedorthists dispense

the biomechanical cure for the foot woes of skiers, professional athletes,

and others in the form of custom orthotics.)

For the last eight years MasterFit’s staff have been teaching

both the basics and the most advanced techniques of boot fitting to folks

on the front line of arguably the most crucial part of the ski equipment purchase

process. First Tracks!! Online got a chance

to experience the MasterFit program first hand this October, and we’re happy

to say, if you can find a MasterFit graduate to coddle your dogs in customized

ski boots, you’ll be glad you did. The program has some drawbacks, and may

not be for every curious recreational skier, but the knowledge imparted is

crucial for any shop technician fitting folks in ski boots.

|

MasterFit’s Steve Cohen (photo Jim Bauman) |

MasterFit Enterprises is the brainchild of former SKI Magazine

editor-in-chief Steve Cohen. Cohen ran the SKI boot test camp for 8 years

before starting up MasterFit. Starting from comprehensive lab testing in

1985, to similarly scientific on-snow testing from 1989 on, Cohen and his

partner Jeff Rich, owner of the U.S. Orthotic Center in New York City, learned

more about the intricacies of ski boots, their interaction with biomechanics

and technique, and the benefits of proper boot fit than just about any other

background could provide.

Cohen and Rich have developed a proprietary method evaluating

and ranking the boots they test that has made the SKI magazine test camp a

critical yardstick for any new ski boot on the market. Recognizing a need

for proper training of ski shop personnel in boot fittings knowledge and technique,

they launched the MasterFit program in 1993, intending for the program only

to be a seasonal diversion from the boot testing camp. What they soon realized,

however, was that they were filling a ski industry market niche that was essentially

empty.

The first students of the MasterFit program would often ask

where their teachers had acquired the cool boot surgery tools and gadgets

used in the class. Cohen soon realized that his students were a perfect group

to whom boot fitting and customization products could be sold. Cohen remembers,

“Every class people would ask, where do you get that thing? After the first

year we did the program, our answer was, ‘You get that from us.’”

Thus in 1994 InstaPrint foot beds were born, and MasterFit became

a new entrant in the boot fitting tools and orthotics market, distributing

their own and others’ tools and developing there own custom foot bed system,

InstaPrint. MasterFit sells their products to ski shops all over the U.S.

and a few in Canada, specializing in those shops that choose to make high

quality boot fitting the cornerstone of their sales and customer loyalty strategies.

Recently, MasterFit engineered a new moldable gel boot material to be used

in place of EVA rubber by boot manufacturers. No longer just a seasonal training

business, MasterFit Enterprises is a unique entity in the ski business world,

with a 100% focus on making ski and snowboard boots fit properly.

MasterFit offers two training courses: a one-day “Associates”

course and a two-day “Masters” course. The Associates course is geared towards

the majority of ski shop personnel who may have some knowledge of boot fitting

techniques, but need a solid grounding in the fundamentals. The Masters course

gets heavy into the anatomy of the foot, biomechanics, and advanced boot fitting

and stance alignment techniques that most of us will thankfully never have

to worry about. The Master’s course is so comprehensive, in fact, that board

certified pedorthists may use the class for credit towards their continuing

education requirements. The courses are held around the country each fall,

with a total of six clinics in 2000. Two are in the east, one in the mid-west,

two out west, and the first ever in Canada. Additionally, MasterFit will

do custom presentations to the likes of Vail Resorts, PSIA, and other ski

industry groups and businesses, adjusting course content to the needs of the

audience.

My day at MasterFit U. started at a leisurely 10 a.m. at the

Stratton Mountain Inn in southern Vermont. Class size can be as big as 25

for the Associates course and 40 for the Master’s course, but our group’s

numbers were a bit smaller. We quickly broke into the two groups after staff

introductions and got down to business. Our group of Associates consisted

mostly of ski shop personnel sent to MasterFit by their shop’s owners. Steve

Cohen pointed out that this demographic will continue to be a source of growth

for MasterFit. Today’s tight labor market means fewer returning seasonal

ski shop personnel, and shop owners must train a whole new crop of shop workers

each fall. Unfortunately, from Cohen’s perspective, a result of this ski

shop turnover has been the tendency for shop owners to turn to boot fitting

products that do not require much knowledge or expertise, like drop-in foot

beds. There will always be a need for boot fitting experts, though, and our

group was put in the capable hands of Greg Hoffman, owner of the renowned

Lab at Stratton, and one of the best boot fitters in the country.

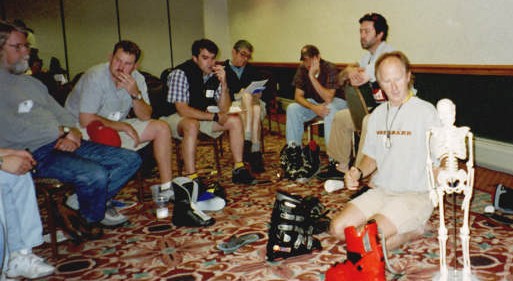

|

Greg Hoffman isn’t afraid of using visual aids to make a point. (photo Jim Bauman) |

Greg engages a group quite well, and keeps his advice as practical

as possible. He often mixed boot fitting advice with economic advice about

ways to maximize ski shop margin, while still satisfying a customer. It is

clear that MasterFit is teaching people who make their living selling ski

and snowboard equipment, and course content is not watered down to the least

knowledgeable attendee’s level, which in this case happened to a certain ski

journalist. When Hoffman asked the class how many years of fitting experience

each attendee had, one particular ski shop manager replied he had five years

experience. When asked why he wasn’t in the Master’s course, the manager

replied, “I’ve been fitting people in ski boots for five years, but I don’t

know how to do it right.” That set the tone for the day, and Hoffman began

the process of teaching us how to do it right.

Throughout the day Hoffman stressed the importance of “shaking

hands with your customer’s feet” in order to get to know them. When a customer

complains of foot pain, Hoffman suggests touching their foot with some force

to determine exact origin of the pain. Hoffman related a story of actually

having a customer pass out from pain during this examination process, but

still recommends this hands-on technique without reservation. Much of Hoffman’s

advice evoked a central tenet of the medical profession: do no harm. It is

easy for an inexperienced boot fitter to cause more problems than they solve,

he warned, despite good intentions.

Many of the boot fit remedies Hoffman demonstrated were extremely

simple. Have a skier with shin bang problems? Perhaps a little bit of the

boot tongue material needs to be removed. Here’s how to do it with a pocketknife

and still leave it looking like new. Have a customer with toe cramps? Pull

out the liner and give a good stretch to make it a bit longer. Have a customer

with chronic cold feet? Determine if their circulation is being impeded at

any of several key points on the foot and take away some liner or boot shell

material at that spot. These pearls of wisdom were eaten up by many of the

attendees, although they often came at odd times throughout the course of

the day. One drawback to the course, to be sure, was a certain lack of structure.

It sometimes seemed as if topics were covered in a haphazard fashion, and

often the instruction time did not seem to be efficiently utilized. These

criticisms aside, there is simply no better way to learn about the fundamentals

of boot fitting than the practical teaching techniques of the MasterFit staff.

The morning of the Associates course was spent going over boot

fitting basics, like shell fitting (determining which size is best by placing

the foot in a liner-less boot shell), basic foot anatomy, and evaluating foot

types in regard to manufacturer boot lasts (the foot shape pattern utilized

by a given boot company). Then it was on to crafting our very own foot bed.

We gathered together, surrounded by a sea of last year’s boots from every

conceivable manufacturer, toaster ovens, heat guns, and other cool toys.

The entire class was then unleashed on one another, casting custom molds of

each other’s feet. After gluing on the “posting,” the underside portion of

the foot bed, we all headed to grinding wheels stationed around the room to

try and grind the bottom of the foot bed flat. Mine came out, well, flat,

in the same way that a person from Colorado would consider the rolling hills

of Ohio flat. Grinding custom beds is tricky business, but the MasterFit

staff assured me they could take a shop newbie and turn them into a competent

grinder in just a couple days. Just have lots of practice blanks lying around.

I developed a new respect for those few who achieve expertise in this arcane

craft. Although a few attendees later complained about the amount of time

spent explaining how to use one of MasterFit’s own products, InstaPrint foot

beds, I felt the physical process of making a custom bed to be an invaluable

teaching tool.

It is evident that the concept of a custom foot bed is the foundation

of the boot fitting process taught by MasterFit. “If you do a lot of fitting

adjustments without the firm foundation of a good foot bed, it’s like building

a fancy house on sand, it’s always going to be rocking and rolling,” explains

Cohen. As anyone who has dissected his or her boots knows, the factory foot

bed is generally the least impressive part of a new ski boot. It looks like

fancy Odor Eater and is often less functional. Boot manufacturers simply

can’t make a foot bed that works well for everyone, so they tend to make stock

foot beds that are little more than a piece of insulation between the bottom

of your foot and the boot liner. The problem with a stock foot bed is that

the crucial part of the boot fitting process is the mating of an essentially

flat inner boot shell floor with the varied and unique topography of the bottom

of the human foot. Stock foot beds usually just aren’t up to the job.

This emphasis on custom foot beds is understandable, but many

recreational skiers just don’t want to spend the extra $100+ that custom beds

cost after shelling out $400+ for a new pair of boots. Steve Cohen realizes

this and does admit that good after market drop-in foot beds exist. They

are sold in good ski shops and are often a definite improvement over the stock

foot beds. Some are available for as little as $25, and may be the best investment

a recreational skier can make to improve their boot fit. However, many of

the clients served by MasterFit graduates make their living on the snow each

year, either instructing, patrolling, or racing, and need or desire the extra

level of control and performance that custom beds provide. Having just experienced

my first few turns on my own custom beds, it’s hard to disagree with that

desire.

After a hearty lunch provided by the Stratton Mountain Inn,

our group headed back to an impromptu jive session about boot fitting problems.

We rapped about folks with knock-knees, serious bunion ickies, and other maladies

of the hip, knee, and foot that make a boot fitter’s job slightly tougher

than landing an F-14 on a carrier at night in heavy seas.

Luckily, the stakes are not quite as high for a boot fitter

as for a Navy pilot, but the application of the wrong remedy can makes a skier’s

life pretty miserable. One good example brought out by the group was heel

wedges. Little neoprene or plastic magic bullets, heel wedges can often be

just what the Boot Doctor ordered to take up that last bit of slop in the

ankle area. They can be used to correct the ramp angle of a foot inside a

boot. They’re often used to help skiers get centered on their skis, and so

on. However, in the case of a skier chronically in the back seat, a heel

wedge can exacerbate the problem through the unconscious compensation for

heel lift by the placement of the hips further back in relation to the feet.

As we went through stories like this you could see lights going on above heads

of the students. Real learning was happening here.

After the jive session we were again unleashed on the tools

and gadgets, this time getting to play with heat guns, grinders, boot stretching

vises, and the like. The theme seemed to be, “abuse these boots in the name

of learning, you may not get another chance!” The merits of grinding away

boot shell material versus heating and “blowing out”, or stretching boots

to alleviate pressure points was discussed, and the practical techniques to

do so were demonstrated and then practiced by the class. It was all very

visceral, and by the end of the afternoon the odor of burnt boots and plastic

shavings hung heavy in the air.

I left MasterFit with a wealth of knowledge about the impenetrably

complex field of ski boot fitting, feeling armed and dangerous with my new

knowledge. Had I already been through a few fitting sessions and been heading

back to a ski shop job, I would have had new found confidence in my knowledge,

not to mention a cool certificate and a very comprehensive boot fitting manual

that MasterFit provides with the course. Ski boot fitting is indeed an art,

one of those skills that cannot be acquired through reading one of those “For

Dummies” books, nor even learned from the font of all information and learning,

the almighty Internet. It takes practice, a breadth and depth of knowledge,

people skills, creativity, and most of all, a love of the process of making

some ski or board better.

Last time I checked, expert boot fitters weren’t making quite

as much green stuff as Java-scripting propeller heads, so it’s a good bet

many of them stick with it because they like what they do. The MasterFit

University staff is full of guys who love what they do and like to teach.

They may need to add a little structure to their curriculum, and back off

on pushing their own products just a tad, but the money spent by any ski shop

on sending their boot fitters to the course will not be wasted.

So about the time your old Flexons are getting a little too

flexible, or you’re ready to abandon your rear-entry dinosaurs from the ‘80s,

and you’re in the market for a new pair of ski boots, do yourself and your

feet a favor: find a competent boot fitter. Finding a MasterFit graduate

would be a great start.

BOOT FITTING TIDBITS

MasterFit Enterprises has just launched a joint marketing program

called “America’s Best Boot Fitters”. The 27 ski shops lucky enough to be

in the program have been certified by MasterFit to be the best in the business.

You may find other good fitters out there, but heading to one of these shops

will ensure that your feet get treated right. You’ll see lists of these shops

in the major ski magazines this winter. Shops will also display banners with

the America’s Best Boot Fitter’s seal.

Steve Cohen recommends that when looking for a boot fitter,

ask how many years the fitter has been working on skiers’ feet. Over 5 years

of experience is preferable. Also ask what kind of custom foot beds they

use. There are “custom” beds out there that do not require any “posting”,

or grinding to ensure flat contact with the boot shell floor. A fully posted

foot bed will provide the most control when prepared correctly. Good boot

fitters can charge upwards of $60 an hour, so make sure you know how long

the process will take ahead of time.

When getting fitted for ski boots, or having custom work done,

go at off-peak hours, and make an appointment. You want the boot fitter to

have your undivided attention. After all, they’re your feet.

A comfortable boot does not always mean an effective skiing

tool. Even though a boot fits well and feels great, it may not put you in

the correct “biomechanical stance” for optimal skiing due to your own anatomy

or boot peculiarities. Canting, boot modifications, and other techniques

might be needed beyond custom foot beds. Cohen warns that only about 5% of

boot fitters out there are qualified to do a full stance alignment analysis

as well as proper boot fitting.

MasterFit’s InstaPrint system is definitely a high-end custom

foot bed. There are other good custom beds out there. Some beds require

you to stand on them after they’ve been heated, which can get a bit hot on

your tootsies. Other beds require you to sit in a chair, nice and still,

with your feet suspended, while a plastic baggy is sucked tight to your foot

by vacuum. InstaPrints are semi-weight bearing, being fitted while you sit

in a chair, and combine the best features of the other two types of foot bed

molding processes.

Steve Cohen noted that he has been writing about the benefits

of custom foot beds for 20 years, but that they are just now starting to receive

serious attention from non-professional skiers. The bad news? You can’t

demo a custom foot bed. The good news? InstaPrint foot beds last about 5-7

years, even when skied 50+ days a year. They might just out last your new

boots.

Shell sizing is the process of putting on a ski boot without

the liner. You stand up, putting your toes all the way forward, just touching

the front of the shell. The back of your heel should have about ½” of room

for recreational skiers, a ¼” for racers and those looking for performance

over comfort. A boot fitter who does not shell size you may not have a ton

of experience.

FYI: Mondo Point sized ski boot shells do not vary for half

sizes. A half size simply has a slightly larger liner in it. If shell sizing

says you fit a given shell size, but your feet feel awfully snug, try putting

in a larger sized liner.

A great source of online information about boot fitting can

be found at the Tognar Toolworks web site.

You’ll find a ton of good information in their paper catalog as well.